TIME

Time is the factor that characterises the hide processing method.

A minimum of 4 weeks are necessary to execute all the processing phases, including a resting one (the second week), to obtain a finished top quality leather, worthy heir of the greatest Tuscan tradition.

The Onda Verde tannery has always processed its top quality products with due care.

Depilation or liming: liming is a process aimed at eliminating hair from the epidermis with chemical processes, where lime is the most important product for the process. The leather also takes the name of “tripe leather”.

Soaking: consists of restoring water to the skin that has lost during salt conservation.

Deliming, bating and Pickling: the pelt start again the cycle in barrel to prepare the hide for tanning, is removed lime still present in the hide and the bating will open the fibers that lime has failed to loosen during calcination.

With Pickling bating stopped and the hide is ready to tannage.

Deliming, bating and Pickling: the pelt start again the cycle in barrel to prepare the hide for tanning, is removed lime still present in the hide and the bating will open the fibers that lime has failed to loosen during calcination.

With Pickling bating stopped and the hide is ready to tannage.

Fleshing: it is a mechanical operation to delete the subcutaneous layer still attached to the residue meat, ‟scarniccio”.

Tannage: the treatment of hide to transfer it in leather and will not be putrescible, there are many types of tannage and we use ‟chrome tannage”. It is a treatment of hides with tanning agents (chemical or natural) that are chemically fixed to the material to stabilize it (wet blue) without compromising its characteristics like its softness, flexibility and fibrous structure.

All these stages are very delicate so are monitored by specialized professionals with tools and chemical reagents, such as a thermometer, a pH, the Baume, the phenolphthalein and bromocresol green.

For this first stage of processing will be used about 5 liters of water for each kilogram of raw hide.

All these stages are very delicate so are monitored by specialized professionals with tools and chemical reagents, such as a thermometer, a pH, the Baume, the phenolphthalein and bromocresol green.

For this first stage of processing will be used about 5 liters of water for each kilogram of raw hide.

SECOND WEEK

Rest period: during these processes the hide has received a lot of chemicals, which should stabilize within, so you need a rest period, the minimum required is one week.

THIRD WEEK

Pressing: it squeezes the hide to remove the water contained in the section and prepare it to selection.

Selection:the expert operator, selects the surface of the hide and characterizes the surface in various selections depending on the finished product to be achieved.

Selection:the expert operator, selects the surface of the hide and characterizes the surface in various selections depending on the finished product to be achieved.

Splitting: this mechanical operation performed with ‟Splitting”, is used for dividing leathers over their entire surface into two separate layers: the grain split (the top layer) and the flesh split (the bottom layer).

With the tool ‟thickness” to test the thickness of the hide in millimeters.

With the tool ‟thickness” to test the thickness of the hide in millimeters.

Shaving: mechanical operation performed with ‟Shaving” to make uniform the thickness of the hide over the whole surface of leather. The thickness of the hide is tested with ‟thickness” in millimeters and tenths of a millimeter.

Retannage: treatment performed after tannage to confer and modify certain characteristics different from those conferred by the main tanning process. It is a specific treatment with retanning and greases, to give the finished product a certain character.

Dyeing: the dyeing in barrel colors the two sides of the hide, with the color most suitable to that end, after which the hide is made stand, namely a rest period of one or two days depending on the finished product.

For this second stage of processing will be used about 5 liters of water for each kilogram of raw hide.

Dyeing: the dyeing in barrel colors the two sides of the hide, with the color most suitable to that end, after which the hide is made stand, namely a rest period of one or two days depending on the finished product.

For this second stage of processing will be used about 5 liters of water for each kilogram of raw hide.

Resetting and Sammying: making wind a mechanical operation with which you removed most of the water that soaks the hide tanned. It is in practice of a pressing of the hide that is performed by squeezing the hide between two cylinders of which the upper covered with felt and a smooth roller, while the fast rotation of another roller blades stretches the hide.

Vacuum: it is an operation of smoothing of the flower and drying, consists in stretching the hide with the grain side of a smooth plate and heated for about 5/6 minutes and through the use of a pump that creates a vacuum on the hide, aspires the water vapor and the moisture contained inside, at the end of processing, the hide should contain approximately a 30/35% of humidity.

Drying: through the suspension with air or other mechanical methods it eliminates the water contained within the hide.

Conditioning: after drying, the hide requires a rest period to stabilize the products placed with the retannage and a natural re-hydration of the surface.

Staking: it is a mechanical stretching used to make traction of the fibers of the hide through stretching and strong forces giving softness and elasticity desired.

FOURTH WEEK

Finishing: finishing includes a series of operations performed on dry leathers to improve the material properties and give a desired appearance and characteristics.

Also protect the leather surface against the adverse impact of external agents.

Also protect the leather surface against the adverse impact of external agents.

Printing: in imitation crocodile, reptile, fish and fantasies, the hide undergoes various treatments, such as printing, plugging, scratch resistance, color silkscreen, laser burns, etc …

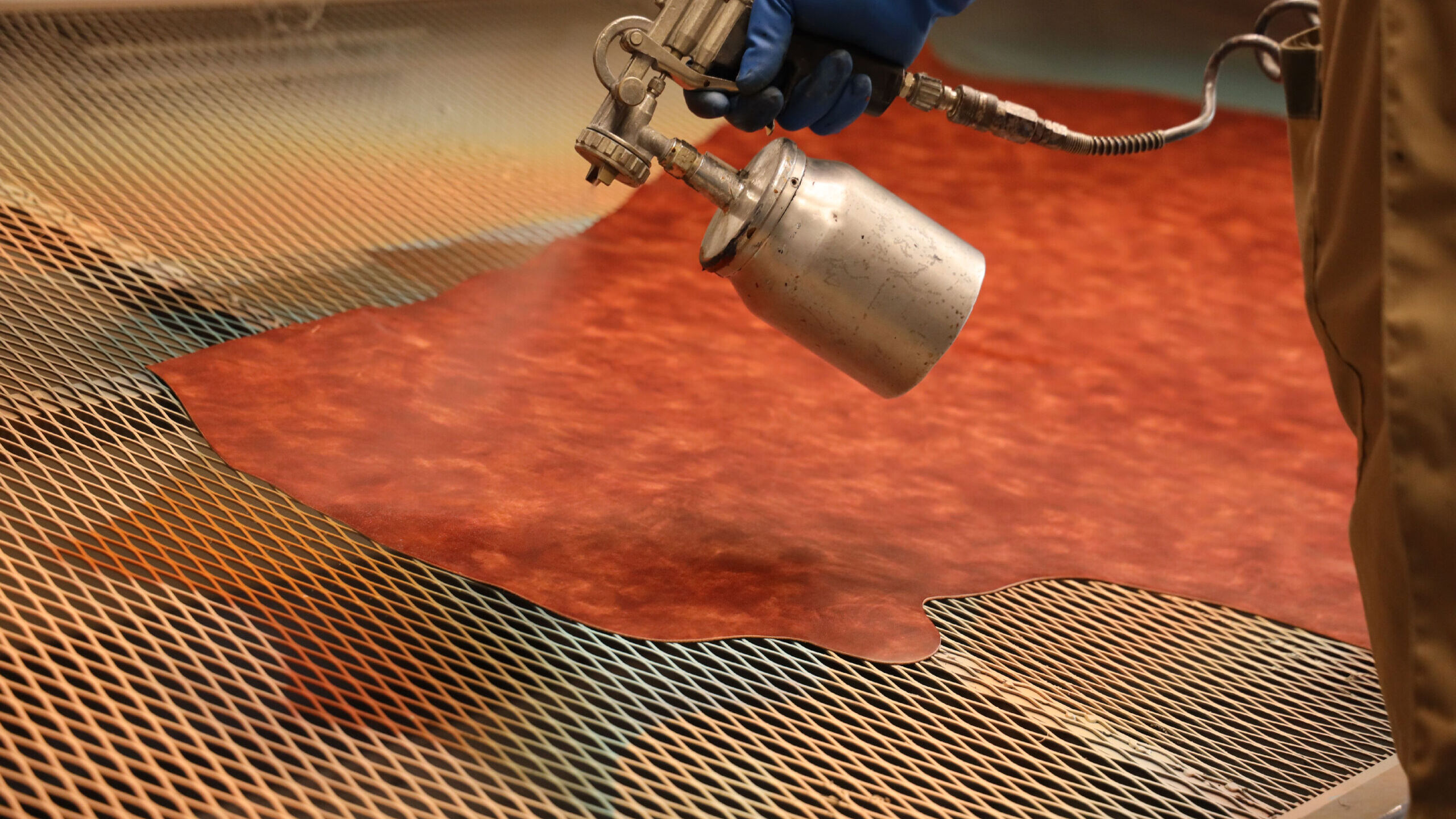

Plugging and spraying: finishing includes various steps in a machine (Spruzzo) equipped with guns that spray liquid chemicals on the hide.

Rolling: there are many machines that help to give different aspects of surface, such as the printing press, grinding machine, ironer, rolling, glazing, boarding, curtain coater, coater, various types of ironer, and others that give a visual and tactile.

Fixing: The phases of finishing for hide type ‟smooth”, are: dyeing, prefondo, rolling / ironing, cover, fixing, ironing.

Ironing: the film created on the surface of the hide will be subjected to other treatments of smoothing, with various machines which give the final look to the surface of hide.

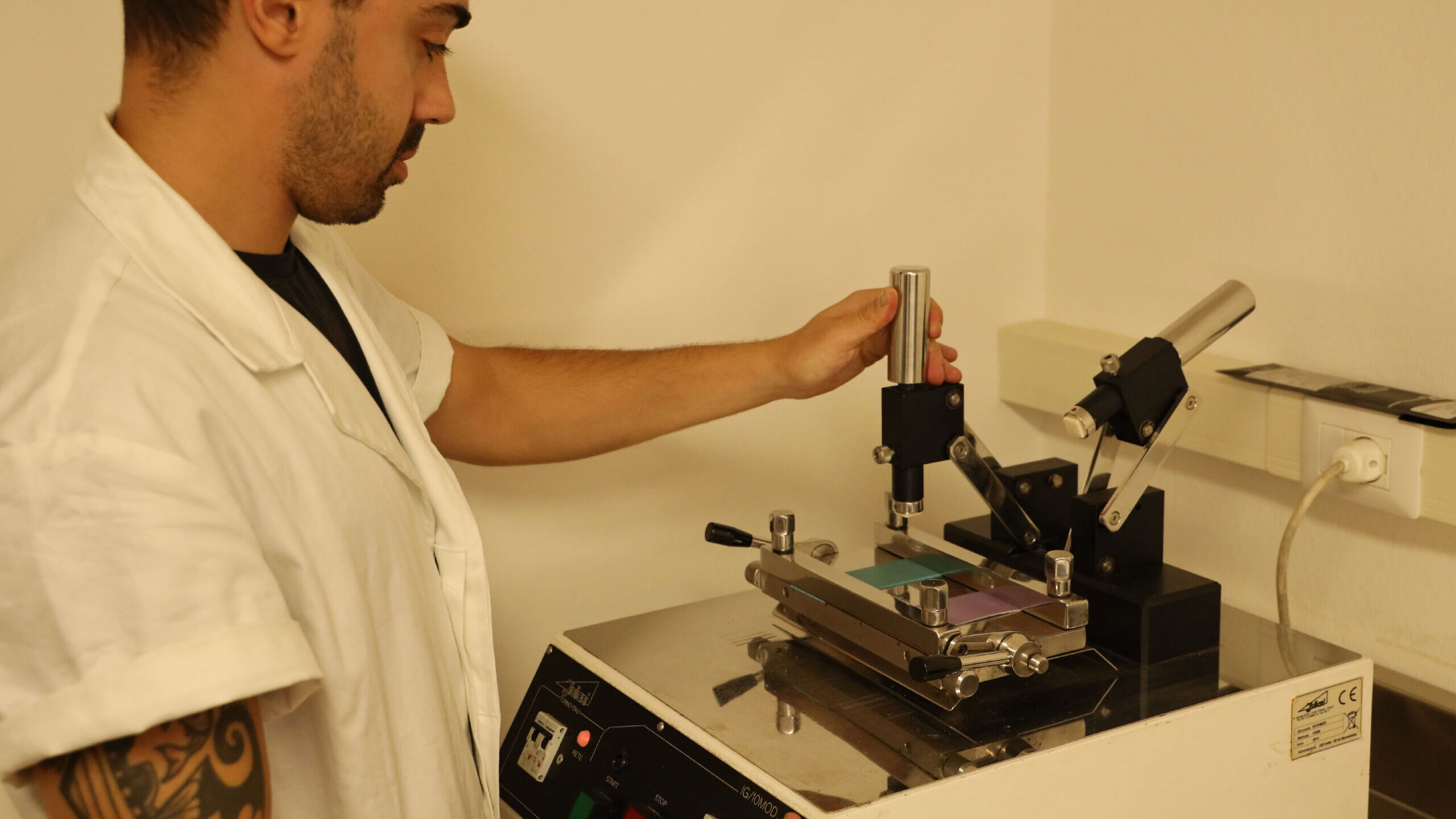

Analysis and testing: for each type of destination of the finished product there are many analysis and requirements that the hide needs to contain and overcome. Sometimes requests for final appearance are omitted certain values / data of minima resistances necessary.

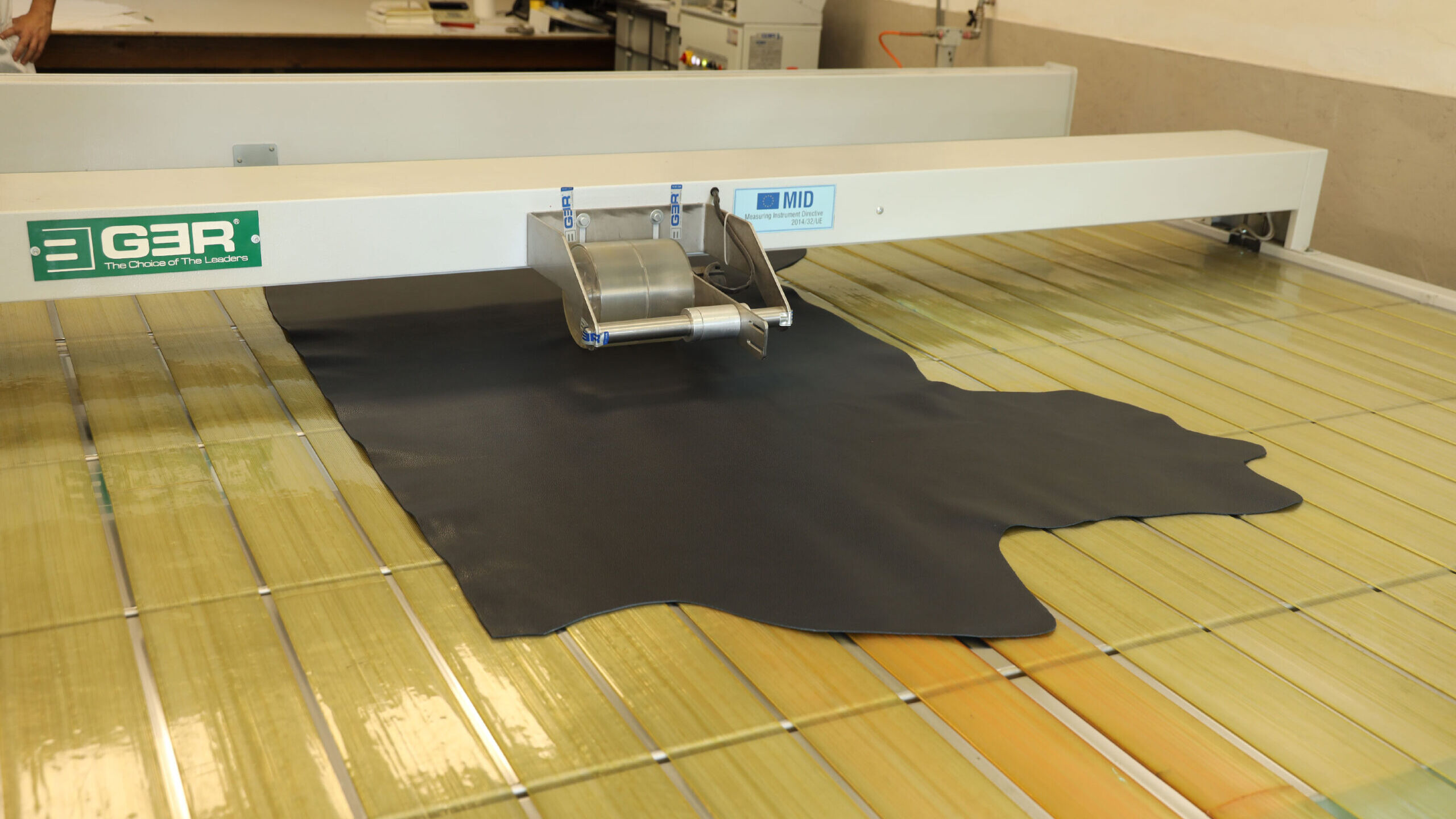

Measuring warehouse: measurement is made with a ‟measuring machine”, which calculates the hide surface in square meters (m2) or square feet (Pq).

The square foot is related to the English foot of 30.48 x 30.48 cm = 929.03 cm2, it takes 10,764 Pq for M2 hide.

The square foot is related to the English foot of 30.48 x 30.48 cm = 929.03 cm2, it takes 10,764 Pq for M2 hide.